Table of Contents

Enhanced Oil Recovery: An Overview

Enhanced Oil Recovery (EOR), also famous as "tertiary recovery," refers to a method of extracting oil that has not yet recovered using primary or secondary processes.

Although primary and secondary recovery procedures work by altering the chemical composition of the oil to make it easier to extract, improved oil recovery works by changing the chemical makeup of the oil itself.

Working of Enhanced Oil Recovery

Enhanced oil recovery procedures are complicated and expensive. Therefore, they're only used when the primary and secondary recovery methods have run out of options. Indeed, depending on circumstances such as oil prices, EOR may not be cost-effective at all. In some cases, oil and gas may be left in the reservoir since extracting the remaining amounts is not profitable.

Three Primary EOR Techniques

To varying degrees, three critical categories of EOR are financially successful:

Thermal Recover

The use of heat, such as steam injection, to reduce the viscosity of heavy viscous oil and improve its capacity to flow through the reservoir is known as thermal recovery. Thermal approaches account for about 40% of EOR generation in the United States, with California Accounting for most of it.

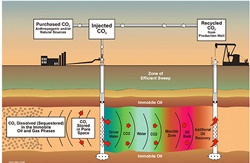

Gas Injection

It employs gases such as natural gas, nitrogen, or carbon dioxide (CO2) to expand in a reservoir and push more oil to a production wellbore or other gases that dissolve in the oil to lessen viscosity and improve flow rate. The EOR output in the United States is roughly 60% due to gas injection.

Chemical Injection

It can include using long-chained molecules known as polymers to improve the effectiveness of waterfloods or detergent-like surfactants to help lower the surface tension that stops oil droplets from migrating through a reservoir.

Talk to our investment specialist

Each of these methods has been limited by its relatively high cost and, in some situations, its unpredictable effectiveness. Pumping steam into the well for heating the oil and making it less viscous is another typical EOR technique. Similarly, "fire flooding," which is setting fire around the border of an oil reservoir to force the remaining oil near the well, can produce similar results.

Finally, various polymers and other chemical structures can be pumped into the reservoir to lower viscosity and boost pressure, albeit these procedures are frequently prohibitively expensive.

Using Improved Oil Recovery Techniques

EOR has the potential to extend the life of wells in proved or probable oil resources, according to oil firms and experts. Proven reserves have a larger than 90% possibility of retrieving oil, whereas probable reserves have a greater than 50% chance of recovering petroleum.

The EOR procedures, unfortunately, can have significant environmental consequences, such as causing dangerous compounds to escape into groundwater. Plasma pulsing is a new method that could help lessen these ecological risks. Plasma pulse technology, developed in Russia, involves radiating oil fields with low-energy emissions, decreasing their viscosity the same way that standard EOR techniques do.

Plasma pulsing may be less environmentally destructive than other current oil recovery processes because it does not need injecting gases, chemicals, or heat into the ground.

Applications for Offshore EOR

Even though EOR applications are primarily used onshore, solutions are being developed to extend EOR's reach to Offshore applications. The Economics of offshore EOR is currently being challenged, as are the weight, space, and power limits of retrofitting existing offshore facilities, as well as fewer wells that are more widely spread, all of which contribute to displacement, sweep, and lag time.

The use of EOR is currently being studied for several offshore projects. With successful subsea processing and secondary recovery methods such as water and gas injection being used in offshore locations, the technology to apply EOR procedures is rapidly approaching.

All efforts have been made to ensure the information provided here is accurate. However, no guarantees are made regarding correctness of data. Please verify with scheme information document before making any investment.