Make-or-Buy Decision

What is the Make-or-Buy Decision?

Businesses have two options when it comes to the production of finished goods. They could either use their In-House team for the task or outsource the job to a third-party. The make-or-buy decision theory can be defined as the outsourcing decision that helps companies evaluate the cost, time, and efforts required for the production internally.

It is also used to figure out the time and cost you will spend if the production is outsourced to the external suppliers. In other words, a make-or-buy decision is the comparison of the internal and external methods of production. You are supposed to take several factors into consideration when making the outsourcing decision. For example, the cost of storage, the professional’s salary, and the time they required are to be considered.

Outsourcing Task Vs Performing Internally

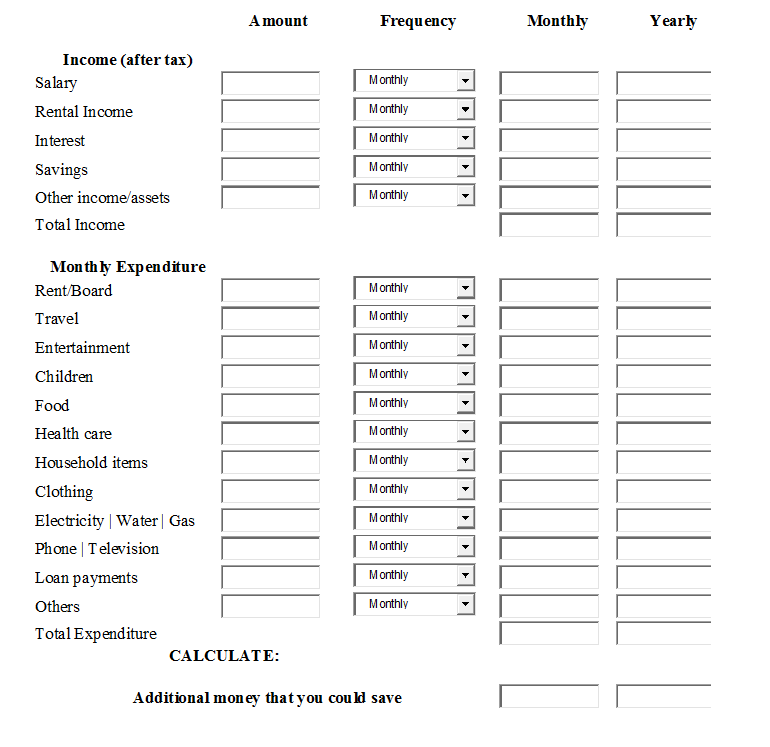

If you are planning to complete the project internally using the in-house production team, then you need to consider the total cost that will incur for the product’s Manufacturing and maintenance. This includes the cost of renting or buying the equipment needed for manufacturing, its repair, labor required to complete the task, storage cost, disposal of the waste, and cost of Raw Materials. If you are making the product using the in-house team, then you need to include the transportation and shipment cost on the price as well as Sales Tax charges. Add to this the wages the labor will charge and the cost of inventory.

The main purpose of the make-or-buy decision is to find out the most appropriate and cost-efficient solution for the project. Usually, companies have to conduct a quantitative analysis to determine and compare the total cost. The main reasons why a company could choose to make the product internally rather than outsourcing the task to a third-party are:

- A qualified and experienced in-house team that’s totally capable of completing the project or the manufacturing task efficiently.

- A large volume of production requirements

- Access to the production equipment and tools

Talk to our investment specialist

If the quality of the production is the main concern and the goods are to be produced in a large volume, then the company might choose to complete the production process internally. Basically, there is no need to hire external suppliers when you have the technology and tools ready for manufacturing.

Buying the finished goods from external suppliers, on the other hand, can also prove to be a cost-efficient solution for certain projects. For example, if you lack a professional and qualified in-house team for the task, then it is best to leave the project to a third-party. Likewise, if you need to produce the goods in a small volume, then it is better to hire professionals than spending hundreds of thousands of bucks on acquiring equipment and technology for production.

If you are planning to outsource the task to external suppliers, you must check their credibility. It is also important to check if the supplier is willing to collaborate with your company for the long-term.

All efforts have been made to ensure the information provided here is accurate. However, no guarantees are made regarding correctness of data. Please verify with scheme information document before making any investment.