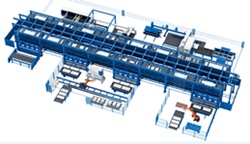

What is a Flexible Manufacturing System?

A Flexible Manufacturing System (FMS) refers to a manufacturing process that can easily adjust to variations in the product's type and amount. Machines and automated systems can be set up to make a wide Range of parts and Handle varying production levels.

FMS can increase Efficiency and minimize production costs for a corporation. Flexible manufacturing can also be an essential part of a make-to-order approach, allowing customers to create their products. Such adaptability may come with a higher initial cost. Compared to more typical systems, purchasing and installing the specialist technology that allows for such personalization may be pricey.

How does it Work?

A flexible manufacturing system is an integrated manufacturing system managed by a giant computer that includes computer-controlled machine tools, transportation, and handling equipment.The functions of both computer-controlled machine tools and handling systems are directed by an overarching control system, which provides flexibility. In addition, these computer systems are built to be easily programmed or combined with other devices, allowing for quick and cost-effective modifications in the manufacturing process and prompt answers to Market changes and mass customization of products.

Machine Flexibility and Routing Flexibility, as previously noted, are two forms of flexible manufacturing systems that can be roughly characterized based on the nature of flexibility present in the process.

Three critical systems make up Flexible Manufacturing Systems.

- The processing stations are essentially CNC machines that have been automated.

- The automated material handling and storage system connects the work machines to improve part flow.

- The central control computer is in charge of material flow and machine flow.

Because it does not follow a set of predetermined process stages, the Flexible Manufacturing System stands out as a system. To achieve maximum efficiency, the process sequence adjusts according to the requirements. The order in which materials move from one tool to the next is not predetermined, nor is the order in which operations are performed at each tool.

Talk to our investment specialist

Benefits and Disadvantages of Flexible Manufacturing System

The essential advantage is an increase in production efficiency. Downtime is reduced because the production line does not have to be shut down to set up for a different product.

The higher upfront expenditures of FMS and the long time it takes to design system requirements for a variety of future needs are disadvantages. The necessity for professional experts to operate, monitor, and maintain the FMS adds to the expense. However, according to proponents of FMS, more automation usually leads to a net reduction in labour expenses.

All efforts have been made to ensure the information provided here is accurate. However, no guarantees are made regarding correctness of data. Please verify with scheme information document before making any investment.